Mud Pump and Mud Circulation System

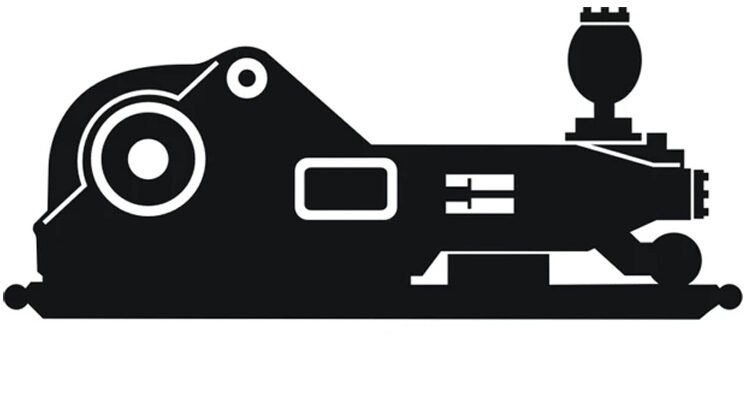

🔻1. Mud Pumps:

- High-pressure pumps that circulate drilling mud through the system.

- Types: Triplex or duplex pumps.

🔻2. Mud Tanks (Pits):

- Stores drilling mud and allows for settling of solids.

- Types: Suction pit, mixing pit, and reserve pit.

🔻3. Mud Mixing Unit:

- Adds chemicals and other additives to the drilling fluid to maintain the desired properties.

🔻4. Shale Shakers:

- Removes larger rock cuttings from the mud returning from the borehole.

🔻5. Desander and Desilter:

- Separates smaller particles that pass through the shale shakers.

- Desander removes particles between 40-100 microns, while desilters handle 15-40 microns.

🔻6. Degasser:

- Removes gas bubbles trapped in the mud, which can affect drilling performance and safety.

🔻7. Mud Cleaner:

- A combination of a desilter and fine screen to further clean the mud.

🔻8. Mud Return Line:

- A pipe that returns the mud with cuttings from the well to the mud tanks.

🔻9. Rotary Hose / Kelly Hose:

- A flexible high-pressure hose connecting the mud pump to the swivel or top drive.

🔻10. Standpipe and Swivel:

- The standpipe is a rigid pipe that channels mud to the rotary hose.

- The swivel or top drive allows rotation of the drill string while maintaining a connection with the mud system.

🔶 Mud Circulation Process

🔻1. Injection: Mud is pumped from the mud tanks through the pumps and into the drill string via the standpipe and rotary hose.

🔻2. Circulation Downhole: Mud flows down the drill pipe and exits through nozzles in the drill bit, carrying cuttings upward.

🔻3. Return Flow: Mud returns to the surface through the annulus (space between the drill string and the borehole wall).

🔻4. Separation and Cleaning: Mud with cuttings passes through shale shakers, desanders, and other equipment to remove solids.

🔻5. Reuse: Cleaned mud is stored in the tanks, where it can be recirculated.