Company History

BJ Services Company is a major provider of specialized oil-field services, ranking second worldwide. Its chief competitors are Halliburton and Schlumberger, which provide similar services to the petroleum industry. BJ’s services primarily relate to pressure pumping activities at new and remediated oil and gas well sites, and include well stimulation, commissioning, sand control, cementing, and casing and tubing services. It also provides inspection and leak-detection services and, in selected geographic regions, markets specialized chemicals. In addition, in the North Sea, Gulf of Mexico, and South America, the company operates, owns, or leases several stimulation vessels. It thus maintains a high industry profile in major onshore and offshore oil fields, including those of the Gulf of Mexico, Texas, California, Canada, the North Sea, much of Latin America, Indonesia, and the Middle East. The company has divisional offices and branches at or near many of these sites, all networked to its central corporate office in Houston, Texas.

BJ Services began to take its current shape in 1990, after it was reorganized and incorporated as a public company and commenced aggressive expansion through acquisitions and consolidation. Its major additions in the following years included the Western Company of North America, acquired in July 1995, and Nowsco Well Services Ltd., bought in June 1996. Nowsco, headquartered in Calgary, Alberta, is BJ Services’ Canadian subsidiary and provides all the core pumping services of the parent company. Other subsidiaries are Unichem (the production and refinery chemicals unit), BJ Process and Pipeline Services, and BJ Tubular Services. Unichem, with headquarters in Houston, specializes in fouling and corrosion problems. It helps gas and oil operators, refineries, and petrochemical producers reach maximum production levels by minimizing the cost of treating these problems. BJ Process and Pipeline Services, headquartered in Aberdeen, Scotland, offers leak detection and commissioning services plus a complete range of services and equipment for the global oil industry, including refineries, process plants, and pipelines. It includes Pipeline Cleaners, a division headquartered in Houston, and a plant in Iowa. Also headquartered in Scotland, BJ Tubular Services provides casing and tubing services and sends highly experienced, veteran crews to drilling sites in Europe, the North Sea, and the Pacific Rim. These various divisions operate within a subsidiary arrangement, which, in 1997, supported over 80 divisional and branch offices throughout the world.

Byron Jackson and the Origin of BJ Services

The man whose initials remain part of the company name was Byron Jackson, a pioneer-inventor who, in 1872, founded the Byron Jackson Company. The firm designed and manufactured pumps and other equipment for miners and farmers, including the Jackson Feeder, a major labor-saving device.

In 1879, the company moved to San Francisco, where, as the Byron Jackson Machine Works, it manufactured prototypes of both deep-well turbine and submersible pumps. The growing business had one major setback in 1906, when San Francisco’s great earthquake and fire destroyed the plant, but Jackson rebuilt his factory, and before his retirement in 1913, he helped design and engineer a new fire prevention and protection system for San Francisco. The system included the first use of fire trucks and fire boats equipped with efficient, high-pressure centrifugal pumps.

Other companies that would figure in the early history of BJ Services were the Independent Torpedo Company of Findlay, Ohio, and the Dunn Manufacturing Company of Oxnard, California. Independent Torpedo was formed in 1905, with a primary aim of “shooting” wells with explosives to induce fracturing in oil reservoirs. Dunn, in 1911, began marketing a new type of casing wrench, an early version of tongs, a major oil-field device. Expansion followed, particularly in the case of Independent Torpedo, which began servicing oil fields of the southwest from its plant in DeLeon, Texas, which opened in 1917. In 1928, Independent merged with the Eastern Torpedo Company.

BJ Expansion Through the Great Depression

In 1929, at the start of the Great Depression, the company established the Byron Jackson Oil Tool Division after acquiring the Dunn Manufacturing Company and some other, smaller companies engaged in manufacturing oil-field tools. It also purchased the Pacific Cementing Company and commenced servicing drilling operations in the Los Angeles Basin in southern California. Three years later, in 1932, it put the Chemical Process Company in operation in Breckenridge, Texas, where it specialized in oil-well acidizing. Then, in 1938, with new oil-field strikes in the Mid-Continent and Permian Basin regions, BJ built a new manufacturing plant in Houston, its future home base. Two years later, amidst World War II, it also entered into an arrangement with Baker Oil Tools, Schlumberger, and Dowell to provide joint oil-field cementing services under the conglomerate name International Cementers Inc.

New Technologies in the Post-World War II Boom

In 1945, BJ developed the first practical air-powered drilling device, the BJ Power Slip, and in the following year jointly developed a prototype jet-shaped charge, making it the first to jet perforate concrete casings for oil wells. It also developed the PL-7 pump truck, a cementing unit with a 10,000 psi capacity. In 1948, BJ introduced a new system for handling drill pipe, ultimately to become the Type V Pipe Racking System, which is still widely used in the industry.

The company’s innovations led to success and inevitable expansion. In 1951, BJ acquired International Cementing. Then, in 1956, it became a subsidiary of Borg-Warner, one of the largest and most innovative industrial complexes in the country. In that same year, BJ purchased the Chemical Process Company, which earlier had merged with the Eastern/Independent Torpedo Company. The move strengthened BJ’s role in fracturing and acidizing services, and opened up new markets, both domestic and foreign.

Expansion Through the 1960s

BJ’s reputation also strengthened as it expanded. The company created 40 service districts to service all the major oil fields in the United States and also established overseas operations in over 20 countries, notably in Canada, Argentina, and Australia.

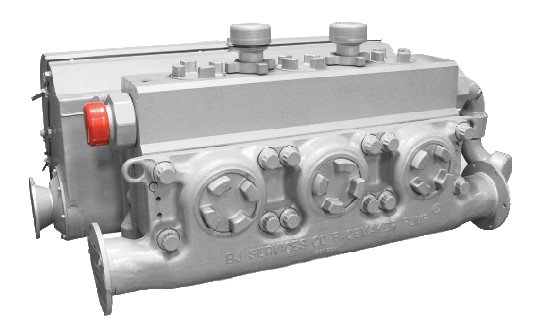

Clearly, BJ had become a leading oil-field service company, noted for its development of new technologies and equipment. In 1959, Phillips Petroleum used tools developed by BJ to drill a well in Pecos, Texas, to over 25,000 feet, at the time the deepest drilled well in the world. In 1962, the company introduced the Pacemaker, a triplex pump that became the prototype for compact pumping skids, which, by 1967, were being used on offshore rigs and various remote locations. These light weight skids could be broken down quickly for transport by helicopter, then reassembled at inaccessible sites for both cementing and drilling services.

Other important innovations followed. During 1967 and 1968, the company introduced new systems, both for handling mud and automatically controlling its density as well as creating cement slurry additives and verifying cement blends. It also developed the BJ Subsea Cementing Plug System, making offshore cementing both more efficient and safer.

Name and Ownership Changes with the Oil Slowdown of the 1970s and 1980s

After the oil boom of the early 1970s, there was a long cooling off in the petroleum industry that reached a nadir in the mid-1980s. During that time, the company went through some restructuring and name changes. First, in 1974, Hughes Tool Company purchased the concern, changing its name to BJ-Hughes Inc. A decade later, in 1985, a subsidiary of Dresser Industries named Titan Services formed a partnership with Hughes, using the name BJ Titan Services, but the partnership dissolved in 1989. That breakup allowed the company to evolve into an independent corporation, BJ Services, formed on May 13, 1990. In July of that same year, the company went public. It became totally independent of Hughes by 1991, when Baker Hughes Inc. sold all its remaining interest in the company.

The 1990s: Rapid Growth Through New Technologies and Major Acquisitions

The newly reorganized BJ Services Company immediately entered a period of expansion in both size and technological development. In 1991, it developed two computer monitoring systems that allowed users precise control over cement slurry mixtures and fracturing fluids. It also began marketing an offshore cementing unit, the RAM (Recirculating Averaging Mixer), and introduced newly developed fracturing fluids (including Spectra Frac, Medallion Frac, and Spartan) as well as CEMFACTS PLUS, a computer software program for design, realtime data control, and post-use analysis in cementing applications. Additional innovative products followed over the next few years, including, in 1993, a proprietary enzyme breaker known as Enzyme G SM, designed to increased the efficiency of fracturing fluid systems, and, in 1995, BJ Sandston Acid, a formula allowing deep oil reservoir penetration for enhancing recovery and production speed.

These technological developments went hand in hand with BJ Services growth through the purchase of other oil-field suppliers, starting with Salvesen Oilfield Technology, Ltd., in 1992. Salvesen, renamed BJS Oilfield Technology Limited, provided casing, tubing, and leak-detection services in the North Sea/U.K. fields and provided BJ with a growing presence in those markets.

In April 1995, after some other minor acquisitions, BJ purchased the Western Company of North America, a Texas company that had developed hydraulic fracturing for oil well stimulation. This acquisition boosted BJ’s domestic revenue base by over 100 percent and improved its competitiveness in both national and international markets. It increased BJ’s share of the domestic oil pumping service to about 30 percent and provided BJ with highly skilled personnel who helped develop more efficient and versatile fracturing fluid systems from the two companies’ diverse products. The consolidation reduced BJ’s inventory costs, saving the company over $40 million annually.

In the next year, BJ bought Nowsco Well Services Ltd., a company, formed in 1962, which developed coil tubing and innovative technologies. Nowsco, whose acronym stands for “Nitrogen Oil Well Service Company,” started from a single office in Red Deer, Alberta, and quickly expanded operations into the United States, the United Kingdom, and Europe, and its purchase gave BJ new domestic, Canadian, and overseas markets. As a subsidiary of BJ Services, Nowsco has made BJ the primary pumping service provider in Canada and, worldwide, a major coiled tubing and leak detection service provider. The operational integration of BJ and Nowsco has resulted in an expanding coiled tubing business and increased cost reductions of over $22 million.

One additional acquisition was the Top Tool Company, Inc., purchased in July 1997. Top Tool provides oil-field tools for rigs drilling along the coast of Louisiana. The purchase has provided BJ with a greater servicing capacity, expanded its downhole tool operations, and improved its tool proficiency.

These major acquisitions have allowed BJ Services to offer increased synergistic services around the world and rapidly increase its sales. Between 1992 and 1996, BJ almost tripled its total sales, from $330 million to $965 million, and it achieved another 50 percent increase the next year, nearly reaching $1.5 billion.

Company prospects appeared excellent, although always to some degree contingent on the price of oil in a volatile market that largely outside BJ’s control. Yet, even during oil price slides and industry slow-downs, the diversification of BJ Services made it a strong, virtually fail-safe enterprise. In the spring of 1998, oil prices slipped lower than anticipated, with a negative impact on oil production in the United States, Canada, and Latin America. However, BJ’s CEO, J. W. Stewart, was able to claim that, thanks to the continuing need to drill for natural gas in the United States, the company’s growth initiatives in stimulation, coiled tubing, downhole tool, and pipeline inspection services were still on target. The company’s reported earnings through the first half of 1998 supported Stewart’s optimistic analysis. Revenues increased by 19 percent and net income by 106 percent over the same period of the previous year.

The core businesses of BJ Services remained what they had been for several years: cementing, stimulation, and coiled tubing services offered across the globe. But, through its acquisitions over the decade of the 1990s, it made strong advances into ancillary, pressure-pumping services, including casing and tubular supply, inspection, and industrial commissioning services. The company took pride in its global, synergistic technologies that allowed it to provide an array of services to even the most remote oil-production sites. It should continue as an industry leader well into the 21st century.

Principal Subsidiaries: BJ Services Company, U.S.A.; BJ Services Company Middle East; BJ Services Company Overseas; BJ Services Company Limited (U.K.); Nowsco Well Service Ltd. (Canada); Unichem; BJ Process and Pipeline Services (U.K.); BJ Tubular Services (U.K.).