Triplex mud pumps are specialized in oil and gas industry for drilling works. It is used to move the drilling fluid, which is also referred to as drilling mud through the drill string to the surface during the time of drilling. They are made in a way that can be handled high pressure and high flow requirement associated with deep well drilling making them essential part for drilling rigs.

The name “triplex” refers to its configuration, which usually consists of three pistons or plungers operating in sequence thus generating hydraulic pressure. This ensures an uninterrupted smooth fluid flow enhancing effective drilling process. The triplex mud pumps convey uniform rates of flow and pressure important for maintaining wellbore stability, cooling of drill bit and transporting rock cuttings to the earth’s surface.

Rotational power is supplied to the mud pump through an external power source like a diesel engine or electric motor. The power end of the mud pump converts the rotational energy through a crankshaft to a reciprocating motion of pistons.

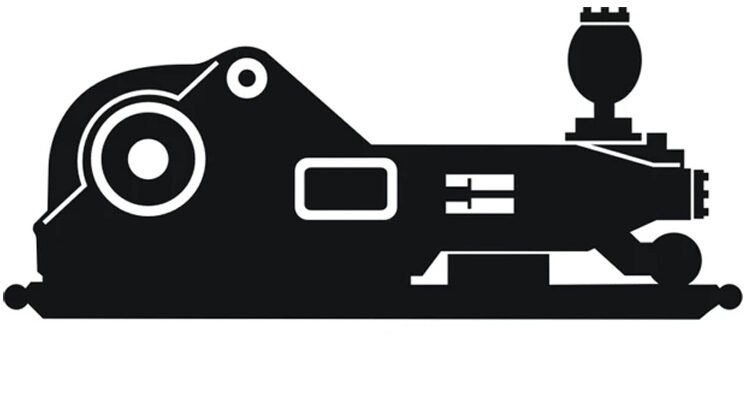

The drilling mud pump is a horizontal triplex single-acting piston pump and consists of two main sections: power end and fluid end.

The power end includes the framework, pinion shaft assembly, crankshaft assembly, crosshead assembly, and crosshead extension rod.

The fluid end includes cylinders (module), valve assembly, cylinder liners, piston assembly, suction manifold, discharge manifold, piston rod, pulsation dampener assembly, etc.